Pharmaceuticals

Biological activity sustained

Biological activity sustained

Faster than freeze drying; higher concentration than TFF

Faster than freeze drying; higher concentration than TFF

System elements FDA approved

System elements FDA approved

Reduced energy consumption

Reduced energy consumption

Short processing times

Short processing times

Low production costs

Low production costs

Low CO2 emissions

Low CO2 emissions

Manufacturing processes of pharmaceutical products are very complex and must respect very restrictive operating conditions. Active molecules, extracted from natural sources, can easily be altered. evapeos® technology is the ideal vector for proteins, vitamins, antioxidants and more. Antibodies have already been concentrated 5x in less than 1/10th of the time taken by lyophilization, using only 2% of the energy.

evapeos® technology operates at low temperature and pressure which ensures the stability of sensitive substances. Products in aqueous solutions can be highly concentrated and solvents can be easily removed without any direct contact with chemicals. Our components have already been FDA validated for several applications in this industry (from ultrapure water production to the concentration of metabolites in fermentation broths) so introduction of the technology should be easy to execute.

Case study

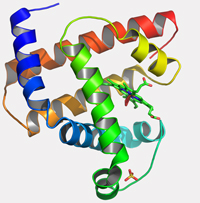

Bovine Serum Albumin Concentration. The figure on the right shows as an example that Bovine Serum Albumin – BSA - can be concentrated more than 8 times with a high recovery yield by means of evapeos® technology.

Nutraceuticals processing is also certain to benefit from evapeos technology.